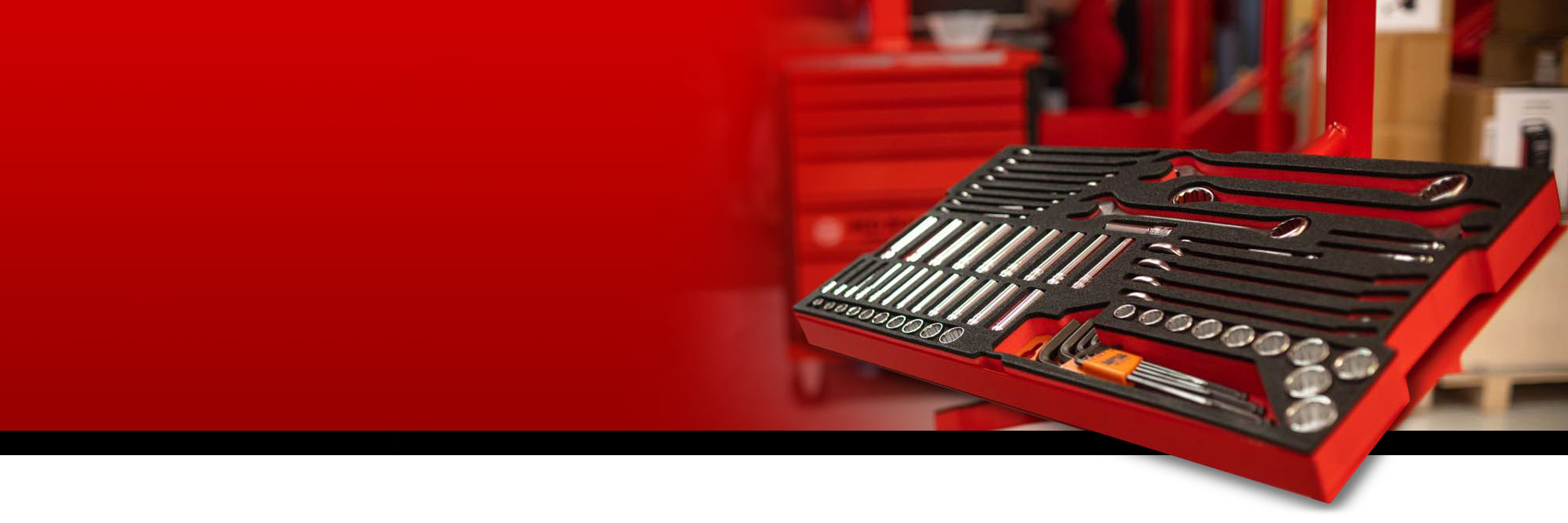

Red Box tool kits have been designed using years of experience and input from a large selection of engineers and tradesmen. All our tool sets are designed to offer a complete solution to our customers, using the highest quality BAHCO, Facom, Draper, and Knipex tools provided with a lifetime guarantee, with each tool embedded in Skydrol resistant foam giving you a complete tool solution system.

Simply put, our tool sets and tool cabinets are the most convenient and economical way to purchase a complete system.

Red Box offer a great range of tool sets, including aviation tool kits, automotive tool kits, mechanics tool kits, metalwork tool kits, electrician tool kits, and HD rigid cases by Explorer Cases, and more.

Custom Tool Foam and

Tools Shadow Boards

Red Box can offer custom CNC foam for your tools, which comes complete with Push Point Technology®. With a simple scanning process, we can design cut out foams for all draw types, which helps to your tools safe on the go, whilst our bespoke CNC tool shadow boards service, enables you to keep your tools safe and tidy at home, work or in the garage.

Design Your Own Tool Kit

If you can’t find an automotive, plumbing, woodwork, electrician, aviation, or any other tool kit that suits your needs, why not design your own? You can do this one of 2 ways:

Go to our Design your own kit page, select the case or cabinet you would like, select the tools you require then simply click request quote. We will have your design and quote back to you in no time at all.

Or

Simply send us your list of tools and let us do the work for you.

toolsales@redboxtools.com

Buy Individual Tools by Leading Brands

If you already have the tool kit of your dreams and simply want to upgrade individual tools, Red Box has you covered!

We are one of the biggest suppliers of BAHCO tools in Europe with thousands of high-quality products to choose from, including handsaws, screwdrivers, wrenches, and much more. If that is not enough, we also stock a great selection of Draper tools, FACOM tools, Knipex tools, Elora tools, and Mountz Torque tools.

Get in Touch:

Also, if you can’t find what you need don’t hesitate to contact the Red Box Tools support team on +44 (0) 2380 254285.

Already have all the metalwork, engineering and aviation tools you need?

Let us design a tool case or cabinet with Shadow Foaming® to keep your tools organised in.

Go to our CNC Shadow Foaming® your tools section for more details.

Visit our sister site Red Box Engineering to learn about our metal powder coating capabilities.